I am fascinated with all things construction, and, in this instance, with the ubiquitous concrete trucks that we see at construction sites. So, I invited myself to visit Mira–Tishman’s 40-story condo development (aka “The Twisty Building”) on Folsom at Spear. I was taken on a tour by two gents with Pacific-Structures, the development’s concrete structure contractor.

I am fascinated with all things construction, and, in this instance, with the ubiquitous concrete trucks that we see at construction sites. So, I invited myself to visit Mira–Tishman’s 40-story condo development (aka “The Twisty Building”) on Folsom at Spear. I was taken on a tour by two gents with Pacific-Structures, the development’s concrete structure contractor.

What I Learned

Concrete trucks start at a mixing plant, one of many in the Bay Area. The plants get raw materials (rocks, etc.) from quarries, then add various materials, chemicals, and water before sending the “mixture” out in the concrete trucks we see on our streets and at the sites.

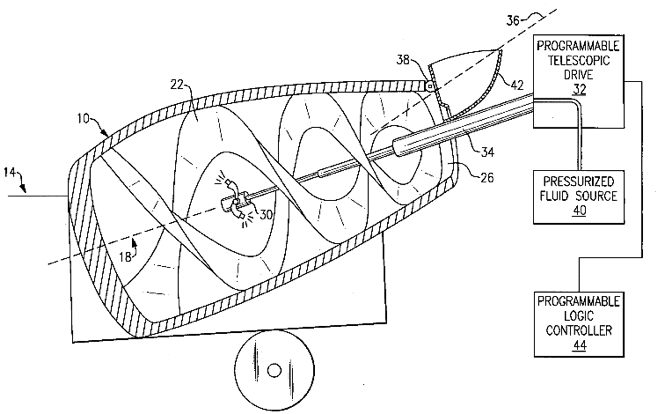

As they proceed to sites, the trucks maintain the concrete’s liquid state through agitation, i.e. the turning of the drum, which is fitted with spiral blades (see accompanying diagram). The rotation is done during transport to keep the mixture from solidifying.

As they proceed to sites, the trucks maintain the concrete’s liquid state through agitation, i.e. the turning of the drum, which is fitted with spiral blades (see accompanying diagram). The rotation is done during transport to keep the mixture from solidifying.

These concrete mixer trucks do not generally travel far from the mother plant. Why? Because concrete begins to set or harden as soon as it is in the truck, so if the truck breaks down on its way to the site, it will naturally harden and a (frantic) call will probably go out for folks with jack hammers.

It can harden fast, depending on the chemicals added to the mix.

A Bit of History

Stephen Stepanian developed and applied to patent the first motorized transit mixer in 1916. This was an effort to replace the horse-drawn concrete mixers used at the time. By the 1940s, engines and truck-frame construction caught up to the need for a rugged vehicle capable of hauling thousands of pounds of wet (“unset”) concrete. As the building boom following World War II went into full swing, mixer trucks came into their own.

Stephen Stepanian developed and applied to patent the first motorized transit mixer in 1916. This was an effort to replace the horse-drawn concrete mixers used at the time. By the 1940s, engines and truck-frame construction caught up to the need for a rugged vehicle capable of hauling thousands of pounds of wet (“unset”) concrete. As the building boom following World War II went into full swing, mixer trucks came into their own.

In the 21stcentury we see them everywhere. Tall, multi-level structures need a lot of concrete!